Innovative measurement, accurate guarding - Explore the efficient charm of box-type ultrasonic open channel flowmeter

In the era of pursuing efficient and accurate water management, accurate measurement of every drop of water is crucial. Today, we are proud to recommend the box-type ultrasonic open channel flowmeter. A collection of high-precision, strong adaptability and intelligent in one of the flow measurement of the new tool.

Our box-type ultrasonic open channel flowmeter adopts the principle of flow rate area method, the flow rate measurement part of the ultrasonic time difference method, through the electronic water ruler to accurately measure the depth of the water, combined with the internal precision processing of the width parameters of the measuring box, to realize the flow rate calculation. The whole process does not depend on the channel parameters, and the calibration is completed before leaving the factory, without the need for on-site calibration, to ensure that the accuracy is worry-free.

Minimization of head loss

Compared with the weir and tank type flowmeter, we use the flow area method, which does not need to change the state of water flow and significantly reduces the head loss, which saves energy and reduces consumption for your project.

Upgraded Measurement Accuracy

Abandon the Doppler point flow rate measurement method, we adopt the time difference method ultrasonic technology, multi-layer cross-layered transducers to accurately capture the average flow rate of each layer of water, effectively reduce the impact of turbulence, improve data stability and accuracy. Especially for the northwestern region with a lot of sediment, the addition of siltation detection function, to ensure that the flow data closer to the real value.

Super adaptability

Multi-channel measurement technology with dense ultrasonic probes enables accurate metering in both complex terrain and bad weather. Anti-freeze expansion treatment and IP68 waterproof protection make the product still stable and reliable in extreme environment.

High standardization, accuracy without worry

Standardized frame design, one-time molding process, to ensure that each piece of equipment before leaving the factory through the high-precision electromagnetic flowmeter calibration of the real flow, that is open and ready to use, the scene without cumbersome calibration, the true value in hand, the efficiency of the multiplier.

Authoritative certification, quality assurance

Box-type ultrasonic open channel flowmeter products (full caliber) to achieve 2 levels of accuracy testing, test report level 2, metrological accuracy of ± 1.5%. Box-type ultrasonic nullah flowmeter, the power of science and technology, guarding the value of every drop of water.

Product Parameters

In this era of the pursuit of efficiency and precision, box-type ultrasonic nullah flowmeter is not only the wisdom of the choice of water resource management, but also the solid backing of environmental protection precise policy. Let us work together to create a smarter and more efficient future! Contact us now to start your accurate measurement journey!

Supply voltage | DC5-24V (red line: power positive; blue or black line: power ground). |

Power consumption | ≤100mA. |

Number of channels | 8~32 channels (according to the specifications of the test box changes) |

Measurement accuracy | Water level +2.5MM,Flow rate ±2%. |

Transducer frequency | 1MHz. |

Transducer working distance | 5cm. |

Calibration method | Real flow calibration before leaving the factory. |

Water level detection method | Ultrasonic water level meter, electronic water scale or radar water level meter. |

Flow rate range with precision guarantee | 0.1~3m/s. |

Communication method | RS485 MODBUS protocol (yellow line:RS485A;green line:RS485B). |

Waterproof rating | IP68. |

Mechanical materials | Stainless steel or aluminum alloy. |

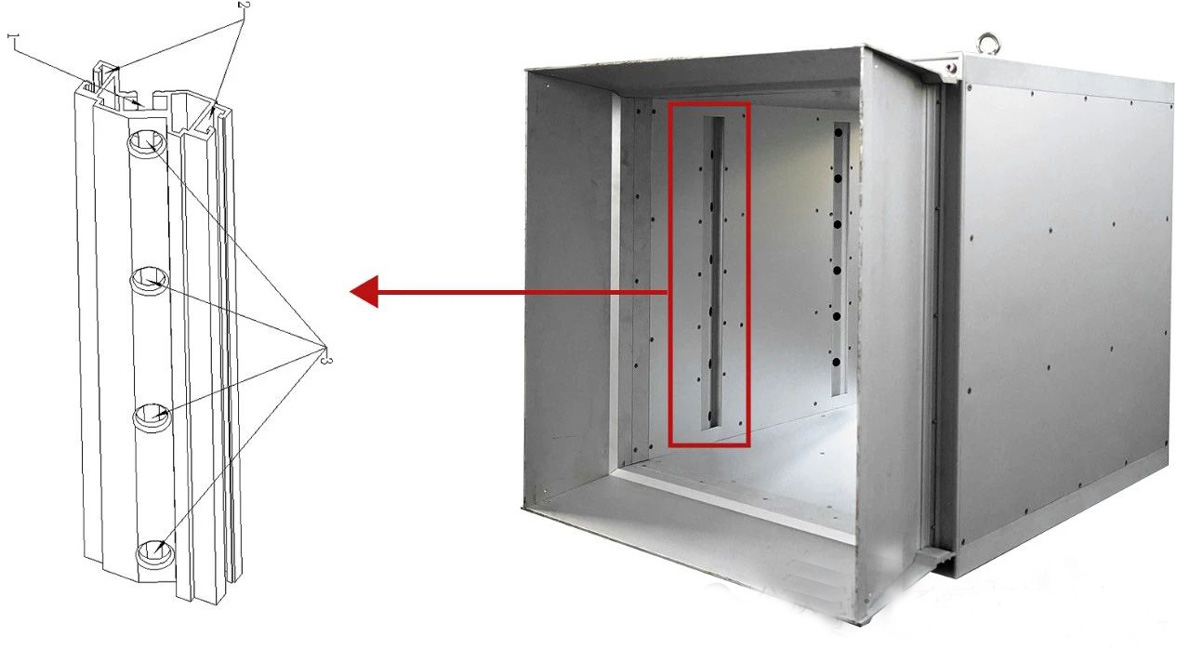

Transducer fixing | Patented technology that the transducer and the fixed surface of the same plane without protrusions to avoid the disturbance of the flow measurement process, making the sampling more stable and reliable. |

Welding and fixing process of the inner compartment | Aluminum alloy welding process is adopted for fixing the inner chamber, which makes the inner chamber smoother and more firmly fixed. |

Signal amplification and processing technology | Adopt signal amplification technology, which can ensure accurate measurement in the case of weak transducer signal. |

Flow measurement | Adopt the principle of flow rate area method |

Transducer arrangement | Cross staggered layers. |

Maximum flow rate error | ±3% or ±2%. |

Flow rate measurement | Adopting the principle of ultrasonic time difference method |

Overflow area | Measurement of water depth by electronic water ruler,then calculate according to the internal width parameter of the measuring box. |

Water level measurement | Three water level method based on water gauge + probe. |

Tank material | High strength 6061-T6 aluminum-magnesium alloy |