Smart Gate Valve

1. High precision

2. Control efficiency

3. Real-time data feedback

4. Energy saving and cost reduction

5. High safety factor

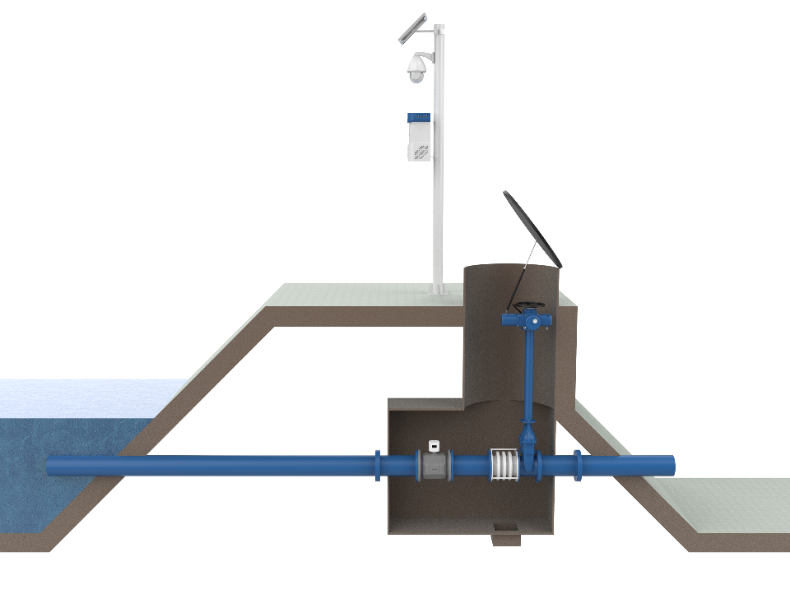

Product Introduction

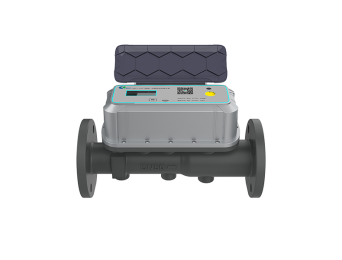

Smart gate valve is an intelligent fluid control equipment upgraded on the basis of traditional electric butterfly valve, which is composed of three parts: valve body, electric actuator and intelligent control system. The valve body adopts disc opening and closing parts (butterfly plate), which controls the circulation and truncation of the medium in the pipeline through the rotation of the butterfly plate, and the rotation angle of the butterfly plate directly determines the flow rate of the medium. The electric actuator acts as a power unit to provide driving force for the operation of the butterfly plate, which can accurately control the rotation angle of the butterfly plate.

The intelligent control system is its core upgrade part, integrating components such as microprocessors, sensors, and communication modules. The sensor can monitor the operating status of the valve in real time, such as butterfly plate position, medium pressure, temperature and other data; The microprocessor analyzes and processes these data, and sends control signals to the electric actuator according to the preset control logic or remote instructions to realize the automatic adjustment of the valve. The communication module supports wired (such as RS485) or wireless (such as LoRa, NB - IoT) communication mode, and can interact with the host computer, monitoring system or cloud platform for remote monitoring and management.

With its intelligent control capabilities, this product is widely used in many industries such as water supply and drainage, sewage treatment, petrochemical, HVAC, and electric power, especially for scenarios that require precise control and remote management of fluid flow, pressure and other parameters.

Advantages of intelligent control of electric butterfly valves

1. High control accuracy: Using high-precision sensors and microprocessor control technology, the adjustment accuracy can reach less than 1%, which can accurately control the flow rate, pressure and other parameters of the medium to meet the precise control needs under various complex working conditions.

2. Convenient remote control: Equipped with advanced communication modules, supporting wireless or wired remote operation, staff can open, close, adjust the valve through computers, mobile phones and other terminals without going to the site, greatly improving the convenience and work efficiency of operation.

3. High degree of automation: It can be seamlessly connected with PLC, DCS and other automation control systems, and can automatically operate according to preset programs to achieve unmanned management. In the system, it can automatically adjust the valve status according to the feedback signal of other equipment or changes in process parameters, ensuring the stable operation of the entire system.

4. Timely data feedback: The operating data of the valve is collected in real time through the built-in sensors, such as the position of the butterfly plate, the pressure of the medium, the temperature, the number of valve switches, etc., and transmits these data to the monitoring center or cloud platform in a timely manner. Users can view this data at any time, making it easy to monitor, analyze, and troubleshoot the operating status of the valve.

5. Energy saving and efficiency: It can accurately adjust the flow rate of the medium according to actual needs, avoiding the energy waste caused by improper adjustment of traditional valves. At the same time, its automated operation reduces manual operation, reduces labor costs, and due to precise control, it can reduce the wear and tear of the equipment, extend the service life of the equipment, and reduce maintenance costs.

6. Safe and reliable: It has perfect protection functions, such as overload protection, overvoltage protection, overheat protection, fault alarm, etc. When the valve has an abnormal situation, it can send an alarm signal in time and automatically take corresponding protective measures, such as stopping operation, preventing the expansion of faults, reducing the risk of accidents, and ensuring the safe and stable operation of the system.