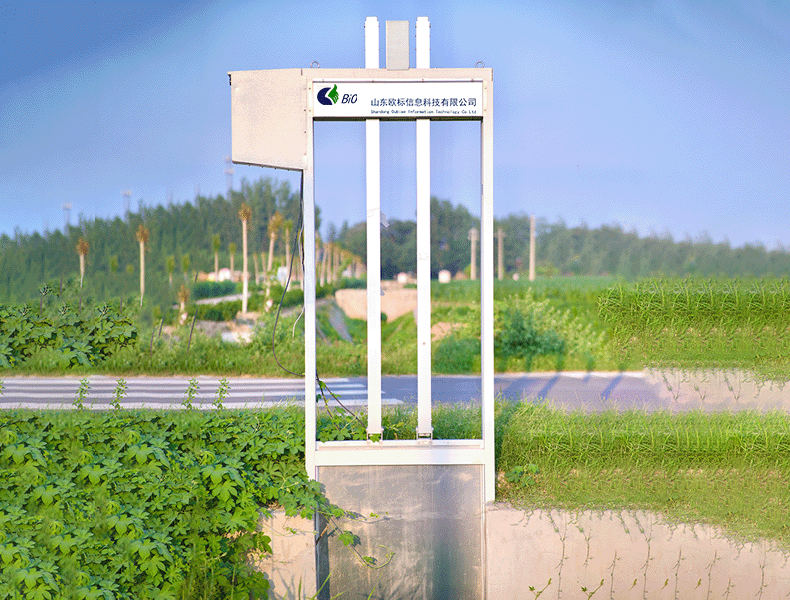

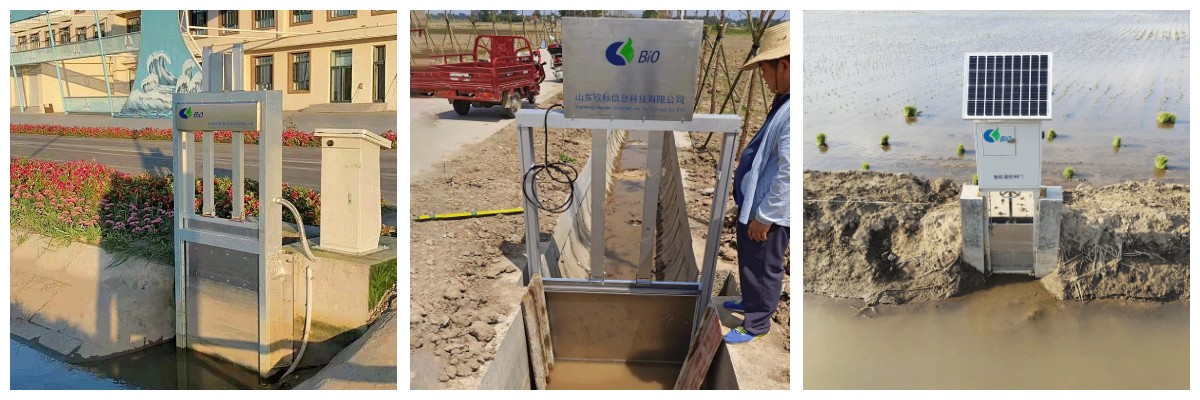

Water Control Gates

1. High-strength T6 aluminum-magnesium alloy material is used

2. Copper-clad worm gear reducer is adopted

3. Automated manufacturing, low error

4. Gate plate mortise and tenon solidification technology

5. Anti-jamming logic design

Water Control Gates are suitable for water resource control, water volume scheduling, etc. of main canals, branch canals, bucket canals, and gross canals. The whole series of intelligent gates are composed of gates, control systems, power supply systems, cloud computing management platforms, management software and mobile APPS. The management platform controls the opening and closing of the gate according to the crop and preset algorithm, and the management personnel supervise remotely to realize automatic irrigation. The gate system can access water level, flow, video and other data, which fully meets the needs of current irrigation area informatization.

It supports a variety of flow metering methods and data transmission protocols, and can select the most convenient module for measurement and control networking according to the field environment. The big data is reported to the management platform in real time, and the system automatically generates a variety of reports, with an ergonomic management interface, which is convenient for the management department to use the data for research and judgment in a timely manner.

Key technologies of intelligent integrated gates

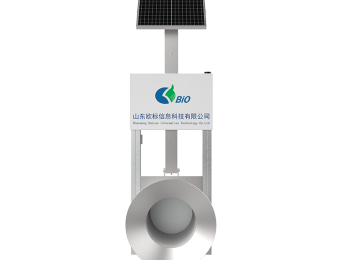

1. It is made of high-strength T6 aluminum-magnesium alloy material, and there are stiffeners inside to increase strength. It is made of advanced heat treatment, and the surface adopts sandblasting and hard anode treatment technology, which has the characteristics of strength, hardness, wear resistance, weather resistance, anti-aging, anti-corrosion and smooth and beautiful surface.

2. It is composed of low-voltage and high-efficiency DC motor and precision reducer. It has good starting performance, speed regulation performance, and mature and stable technology.

3. The profiles, seals and gate plates and frames of the gate are all processed by our own molds;

The processing equipment is all customized automatic CNC machine tools to ensure the consistency of profile processing and avoid deformation caused by gate processing errors.

4. Waterproof mortise and tenon sealing technology on the side of the gate panel:

The gate plate column seal adopts the traditional woodworking mortise and tenon structure, and the nylon seal (mold opening customization) and the gate plate column are embedded with mortise and tenon to ensure that the sealing strip will not fall off during the opening and closing process of the gate, ensuring long-term sealing.